Indian Scout Racing Valve Guides

Please note: Gary Stark of Starklite Cycle is now selling high-quality Scout Valve guides. He has them in Std. and +.002" ODs. I have seen many Scout cylinders, where the hole in the cylinder for the valve guide is worn out, either from rust or abuse. If his guides aren't big enough, then you can make new custom guides from my drawing found below. For a Scout, the cold installation interferance fit must be between .001"-.0015". This is important, or you will have problems.

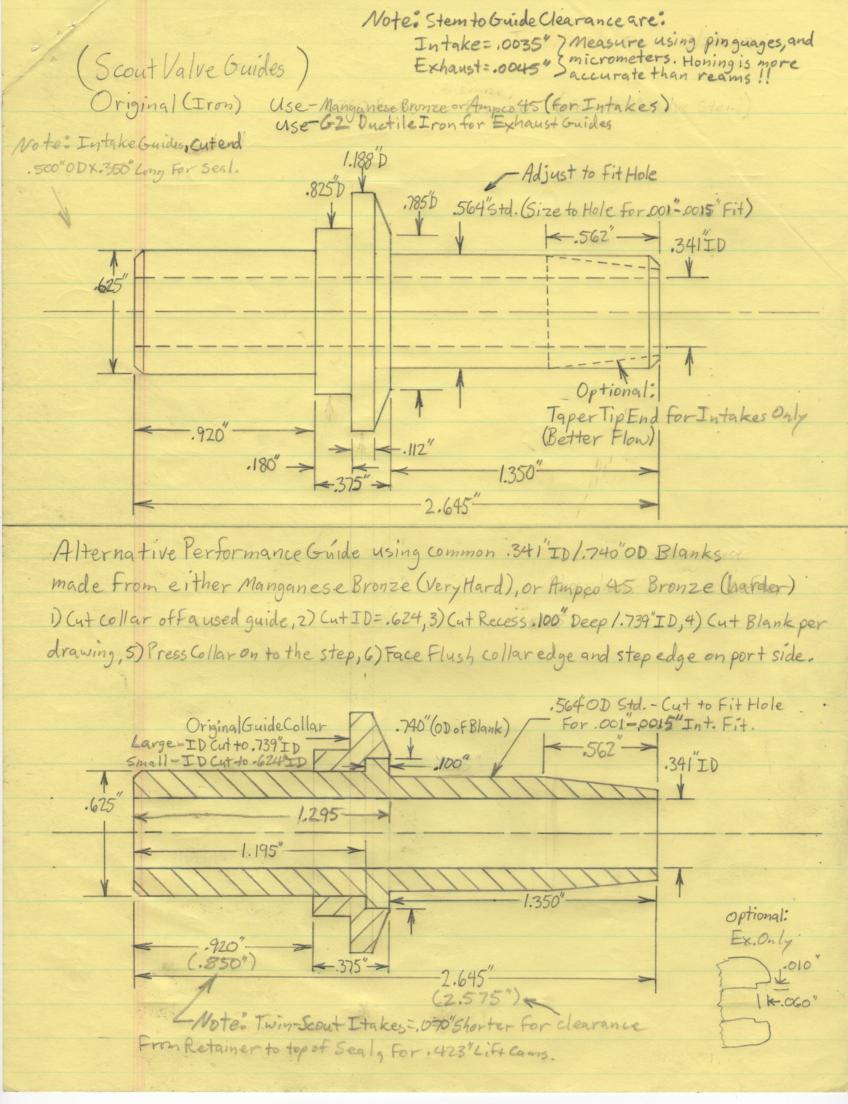

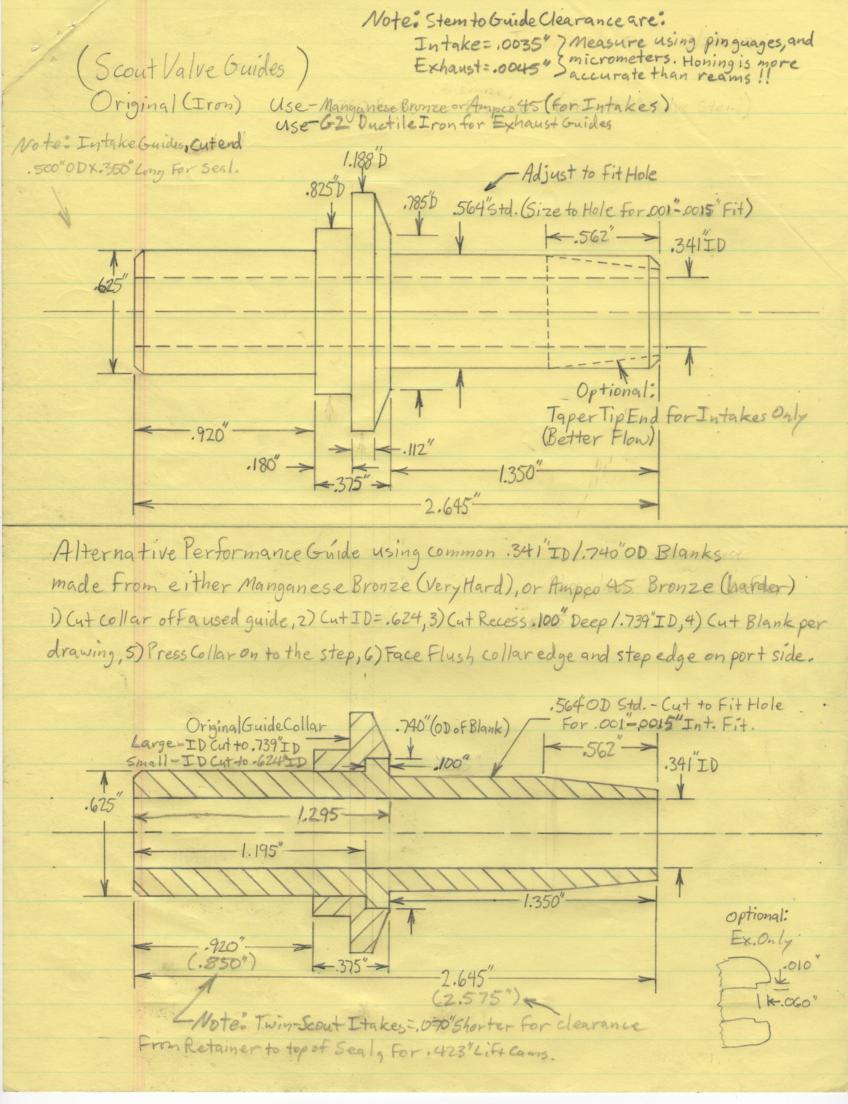

Here is a drawing for making custom Valve Guides for Scouts. ALL of the valve guides sold by the aftermarket vendors are junk! I know, because I've wasted alot of time, and money with valve guides that are too soft, too short, etc. I found that Manganese-Bronze works well for Intake guides (and for Exhaust guides on light duty Scouts). For Exhaust guides in racing 45"ers, 58" strokers, or otherwise "severe duty" use, I recommend using G2 "Ductile Iron". I have had to go to www.pppcenter.com to get some valve guide blanks made from the G2 Ductile Iron. They aren't cheap, but they work great! For the Intake guides, I buy Manganese-Bronze blanks for Harley-Davidson use (part#: UVBG-341) from www.goodson.com, and I make a 2-piece guide using the spring pearch collar from a used Scout, or Chief valve guide. Make sure the collar has no more than a .001" interferance fit, or they will crack! There is a step machined into the blank, that will help locate, and lock down the position of the guide. The guides will need to be made to fit the guide holes in YOUR cylinders. I have found that ALL Scout guide holes are different, and never the factory spec size. Each guide needs to be carefully made to offer an interferance fit to the hole by between .001" - .0015" fit. This is very important! Too loose, and the guides will wear out the OD's, and the hole itself. Too tight, and they will crush-in some where they are captured in the cylinder after a few heat cycles. If they crush-in after being heated, the center of the guide hole will become smaller (bell shaped hole), and can seize your valve stem. It is a good idea to precisely hone the guides to .0035" for Intakes, and .004" for Exhaust initially, then do a tear-down, and re-hone them to relieve the crushed-in portion of the center of the guide hole. It shouldn't crush in very much more. The metal thickness of the guides where they fit into the cylinder is very thin, so they can't resist the high pressure of a hot cylinder. Chiefs are thicker, and don't tend to have this problem.

There are a couple extra options available. First, I like to use common Teflon Valve Seals on the Intakes ONLY! You can machine the spring end of the guide to an O.D. of .500" for a length of .350". Taper the end, so the seal will go on, and make a tool for pushing the seal on, with the valve in place. The seal will keep oil out of the combustion chamber, which makes hard deposits that just ruin you rings, pistons, and cylinder walls. Another mod is to taper the port end of the guides for Intakes only for better flow. The Exhaust should be blunt, and bullet shaped. Another is a mod done by the people at "Axtells". They do a small cut inside the port end of the Exhaust guide to act as a turbulence ring to try and keep exhaust gasses out of the guide. You make an internal cut at .010" per side, and only .060" deep. I don't know if it really works, but Axtells swears by it. Another tip is to make sure your valve cover inners are a loose fit on the guide, so it can be shifted slightly, so the valve cover threads line up better.

CONTACT INFORMATION:

James R. Mosher

1-505-466-7870